TB 3-6665-313-50

Table 4. Gage Performance Limits

Acceptable

Scale major

manometer indications

division indication

(inches of water)

Min.

Max.

1.16

0.84

1

2.16

1.84

2

3.16

2.84

3

4.16

3.84

4

5.16

4.84

5

6.16

5.84

6

7.16

6.84

7

8.16

7.84

8

the gage reading by one graduation (corrected).

b.

Adjustments.

Bubbles should form at the tip of the tube.

(1) Turn the BLEED VALVE to obtain an

(5) If bubbles do not form, slowly open the

indication of 2 inches of water (corrected) on the gage.

drain cock at the bottom of the bubbler assembly bowl,

(2) If bubbles form at the tip of the tube,

and allow the water to drain until bubbles form.

open the fill cup valve, add a small quantity of water,

(6) Repeat (1) through (5) above as

and close the fill cup.

necessary until no bubbles form at a corrected 2 inches

(3) Repeat (2) above until the bubbles no

of water gage reading and start to form at one

longer form.

graduation lower.

(4) Turn the BLEED VALVE to increase

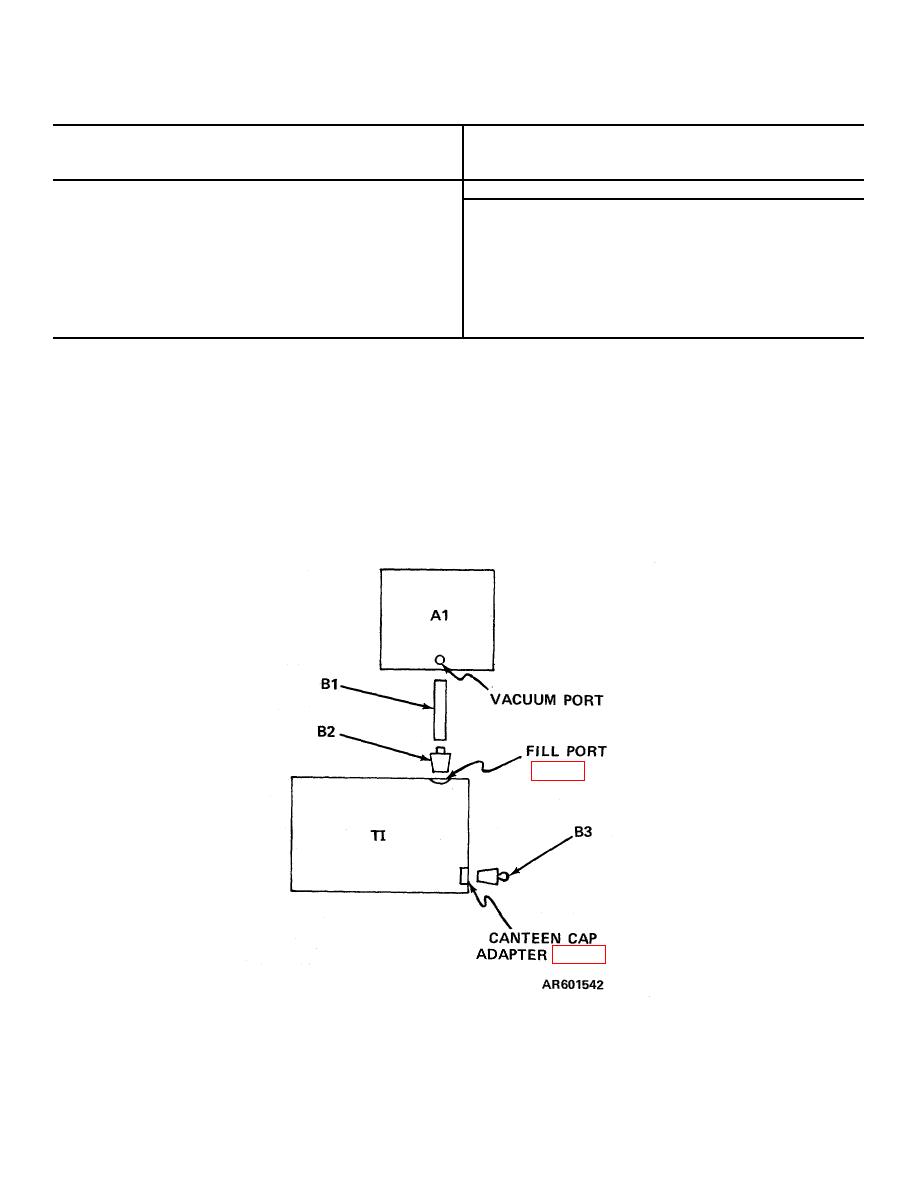

Figure 3. Gage performance test equipment setup.

5