TB 9-4920-465-24

(3) Set the pneumatic pressure standard no. 1 to absolute mode and psi units and

record the current barometric pressure.

(4) Turn the Blade Check and Fill Unit's PRESSURE REGULATOR fully counter-

clockwise, and the NITROGEN SHUTOFF VALVE to the off position.

(5) Connect compressed gas cylinder to TI NITROGEN SUPPLY INLET. Set the

NITROGEN SHUTOFF VALVE to the on position.

(6) Set the pressure standard no. 1 to gage mode and psi units. Using the pressure

regulator on the Nitrogen bottle and the TIs PRESSURE REGULATOR, apply the

pressure settings for the TI indications in table 3, for 4 and 8 psi. Record the readings on

the pressure standard 1 as well as the BLADE PRESSURE indicator at each point.

(7) Change to pressure standard no. 2 for the 12 psi and above settings. Repeat step

3 for the remaining, settings 12 psi and above.

(8) Calculate the difference at each point according to the following equation:

Error = Pb + (14.70 Pa) Ps

TI Reading + (14.70 - Barometric pressure) - pressure standard.

Pa Barometric pressure in psia from step 3.

Ps Reading from pressure standard at each data point in step 6.

Pb Reading from BLADE PRESSURE indicator at each point in step 6.

(9) The error indication must be within 0.09 psig.

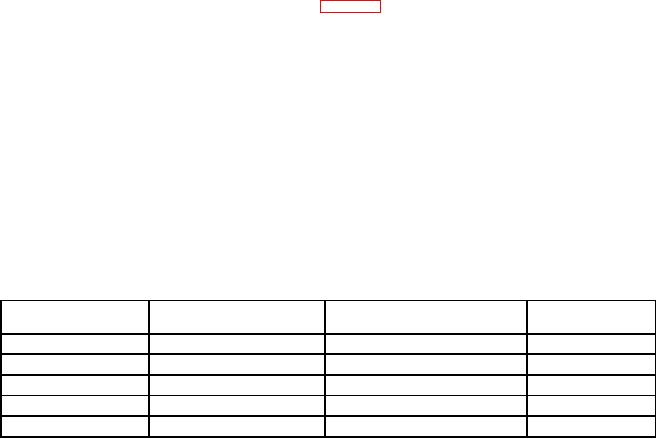

Table 3. Pressure Readings

TI reading

Pressure standard reading

Error

TI indication (psi)

(psi)

(psi)

(psi)

4

8

121

16

20

1Switch

to pressure standard no. 2.

b.

Adjustment. No adjustments can be made.

9. Temperature

a. Performance Check

(1) Remove thermometer from case.

(2) Place TI and standard thermometer side by side in vertical position, using a

support stand. Allow approximately 15 minutes for TI to stabilize.

(3) Compare indication of TI and standard thermometer.

(4) The reading must be within 4 F. If TI reading exceeds the standard

thermometer by more than 4 F replace the TI's thermometer.

b. Adjustment. No adjustments can be made.