TB 9-4931-530-40

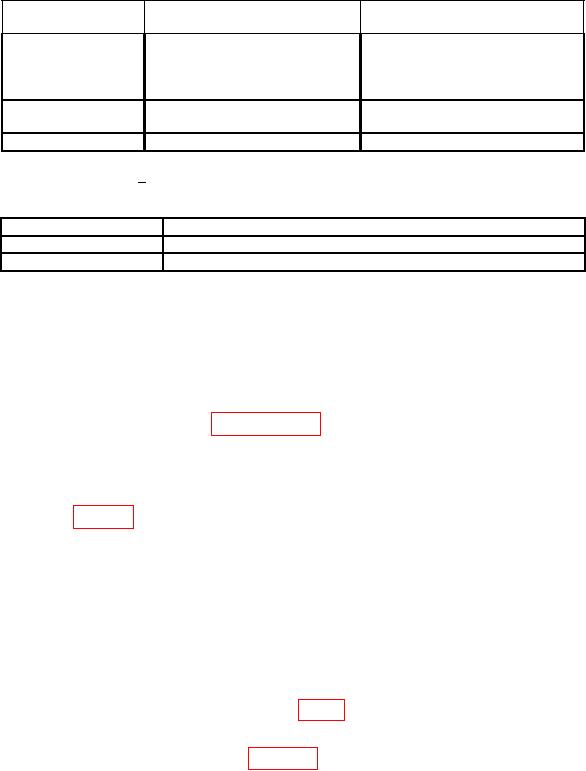

Table 2. Minimum Specifications of Equipment Required

Manufacturer and model

Common name

Minimum use specifications

(part number)

1

(7901267)

GAGE BLOCK

Range: 0.101 in.

1

0.125 in.

0.149 in.

Accuracy:2

SINE PLATE

Range: 5 in.

GGG-B121B (GGG-B121B)

2

Accuracy:

SURFACE PLATE

Accuracy:

Grade A

36"X48" (GGG-P-463)

1Two

required

2Combined

accuracy is +0.00024 in.

Table 3. Accessories Required

Common name

Description (part number)

C CLAMP1

GGG-C-406 (GGG-C-406)

STEEL PARALLEL1

GGG-P-61 (GGG-P-61)

1Two

required. Limited deployed item.

CALIBRATION PROCESS

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the calibration

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the results of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this procedure. Additional

maintenance information is contained in the manufacturer's manual for this TI.

d. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

a. Connect TI SENSING HEADS A and B (fig. 1) to GAGE HEAD input A and B on TI

rear panel.

b. Assemble equipment as shown in figure 1.

c. Set TI switches as listed in (1) through (3) below: