TB 9-5210-204-24

(3) Adjust micrometer ratchet as necessary to obtain a measurement of the ball

diameter. Note indication to the nearest 0.0001 inch.

NOTE

If TI has a 0.001 inch readout micrometer, read to the nearest

one-half minor division. If TI has a 0.0001 inch vernier, read

direct.

(4) Repeat technique of (2) and (3) above for points B, C, D and E.

ball micrometer tester small ball with large ball (0.250 in.) and repeat technique of (2) through

(4) above.

(6) For 0.001 inch readout micrometers, verify that the five readings have a

maximum difference of one-half of a minor division for each ball. Use tolerances in table 4

for 0.0001 inch readout micrometers. If readings are within tolerance, proceed to

Table 4. Parallelism Tolerance for Outside Micrometer Calipers

Test instrument

Size

Range

Tolerance

Inches

Millimeters

Inches

Millimeters

Inches

Millimeters

1

25

0 to 1

0 to 25

0.00010

0.0025

2

50

1 to 2

25 to 50

0.00010

0.0025

3

75

2 to 3

50 to 75

0.00020

0.0050

4

100

3 to 4

75 to 100

0.00020

0.0050

5

125

4 to 5

100 to 125

0.00020

0.0050

(7) If TI basic length is 1 to 5 inches, perform technique of (8) through (15) below:

(8) Place vise on a flat level surface.

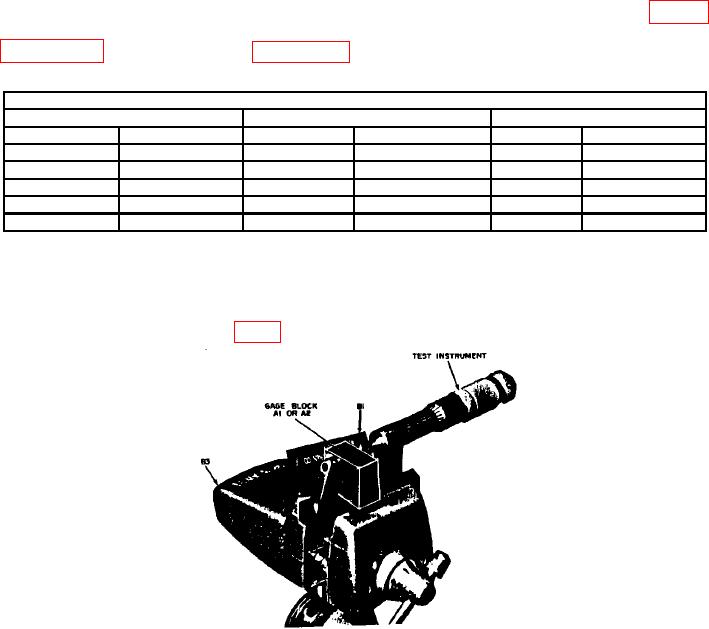

(9) Place TI in vise so TI is at a 90 degree angle from work surface and spindle is

parallel to rubber jaws of vise (fig. 2).

Figure 2. Parallelism Test - Equipment Setup.

5