TB 9-5210-210-50

furnished with dial indicator calibrator (A1, table 2).

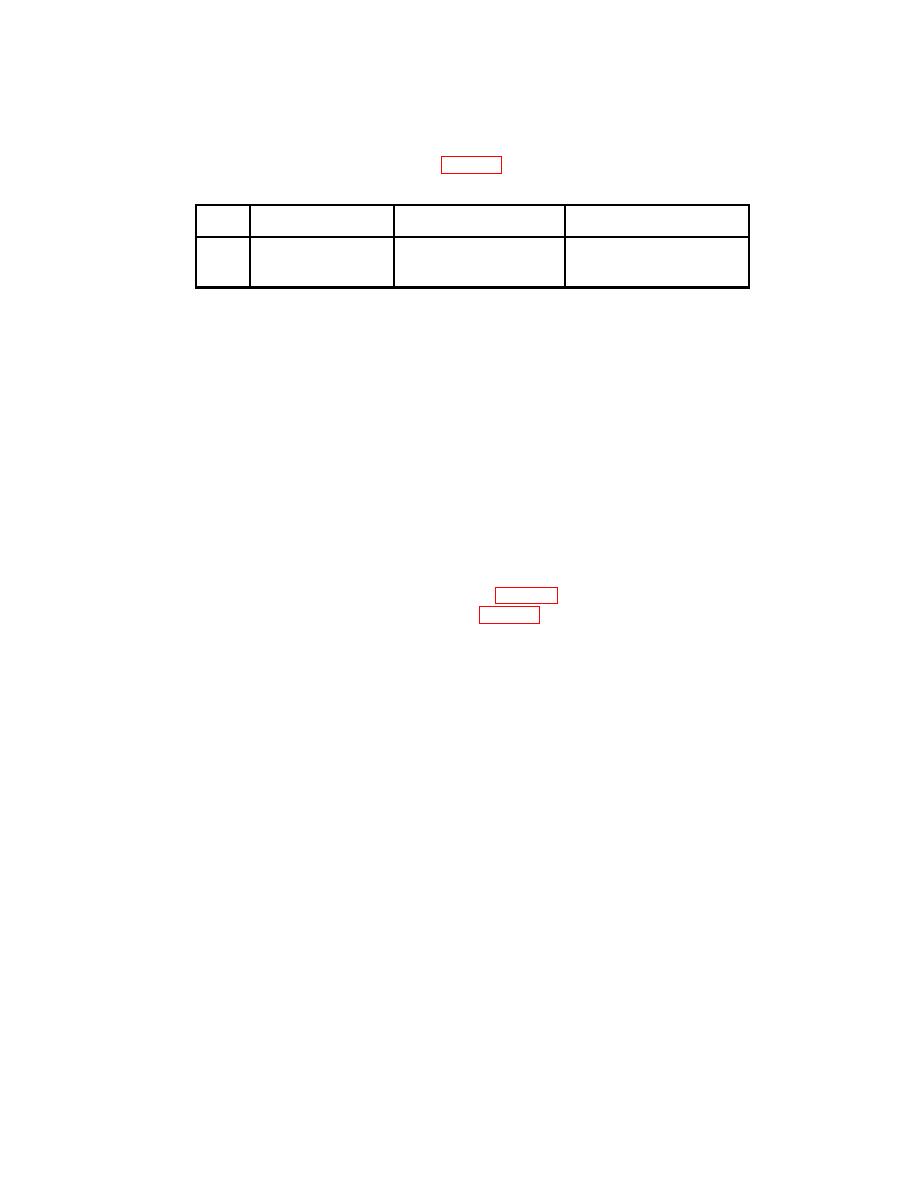

Table 2. Minimum Specifications of Equipment Required.

Common Name

Minimum Use

Manufacturer, Model and

Item

Specifications

Part Number

A1

DIAL INDICATOR

Federal Products Corp.,

Range: 0.00005 to 1 in.

1

Model 400B-1

CALIBRATOR

Accuracy: 0.00001 in.

(MIS-10327)

(0.00004 in.)

1Equipment

limitation: accuracy 0.00004 inch.

SECTION III

NOTE

Unless otherwise specified, verify the results of each test and

take corrective action whenever the test requirement is not

met before continuing with the calibration.

6. Preliminary Instructions

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name and item identification number as listed in table 2. For identification of equipment

referenced by item numbers prefixed with A, see table 2.

c. Loosen bezel locking screw (fig. 1) and rotate bezel 360.

that the contact point is tight on TI spindle.

e. To verify that the TI is operating properly, perform the procedures listed in (1) and

(2) below:

(1) Depress spindle or contact end to internal stop and release. Spindle or contact

end should return to extended position freely and without hesitation.

(2) Record the position of the hand at the extended position and at the depressed

position for future reference.

NOTE

During calibration of a style C TI, the lever arm shall not

deviate more than 15o from the horizontal plane of the TI. To

ensure that the level arm does not deviate, the contact point

lever must be positioned horizontally at midrange to minimize

any cosine error.

3