TB 9-5210-216-24

procedure. The following peculiar accessories are also required for this calibration: Vise,

(39B148).

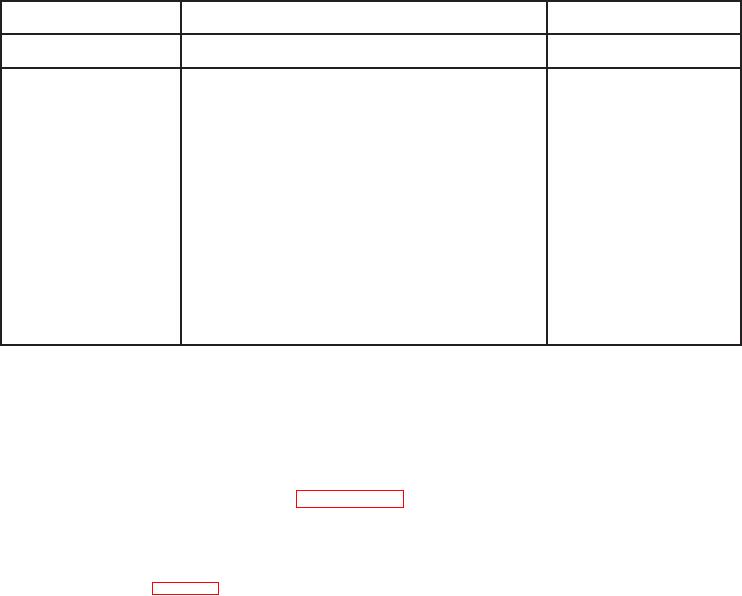

Table 2. Minimum Specifications of Equipment Required

Manufacturer and model

Common name

Minimum use specifications

(part number)

GAGE BLOCK SET

Range:

0 to 6 in.

(13534019)

Accuracy:

Grade AS-2

THREAD PLUG GAGES1

Range: 0 to 1 inch including sizes

Leitech Inst.

-36, -56, 5/8-11, 5/8-24, -16

.5-36 UN

1 to 2 inches including sizes

.50-56 UN

1-6, 1-12, 1-18, 1-28

.625-11 UNC

2 to 3 inches including sizes

.625-24 UNF

2-6, 2-12, 2-18, 2-28

.75-16 UNF

3 to 4 inches including sizes

1.5-12 UNF

3.5-6, 3.5-8, 3.5-12, 3.5-16

1.5-18 UNEF

4 to 5 inches including sizes

1.5-28 UN

4.5-6, 4.5-8, 4.5-12, 4.5-16

1.5-6 UNC

5 to 6 inches including sizes

5.5-6, 5.5-8, 5.5-12, 5.5-16

Accuracy:

0.010 - 0.825 inch 0.000040 inch

0.825 - 1.510 inches 0.000060

1.510 - 2.510 inches 0.000080

2.510 - 4.510 inches 0.000100

4.510 - 6.510 inches 0.000130

1Non-set

configuration calibration standard.

CALIBRATION PROCESS

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the calibration

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in tables 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this procedure. Additional

maintenance information is contained in the manufacturers' manuals for this TI.

d. Unless otherwise specified all controls and control settings refer to the TI.

7. Equipment Setup

a. Remove TI from protective case.

b. Visually inspect TI for any damage that will affect the accuracy of measurement.

c. Rotate thimble several times along full length of thread range to determine if

roughness, binding, or irregularities occur.