TB 9-5210-218-40

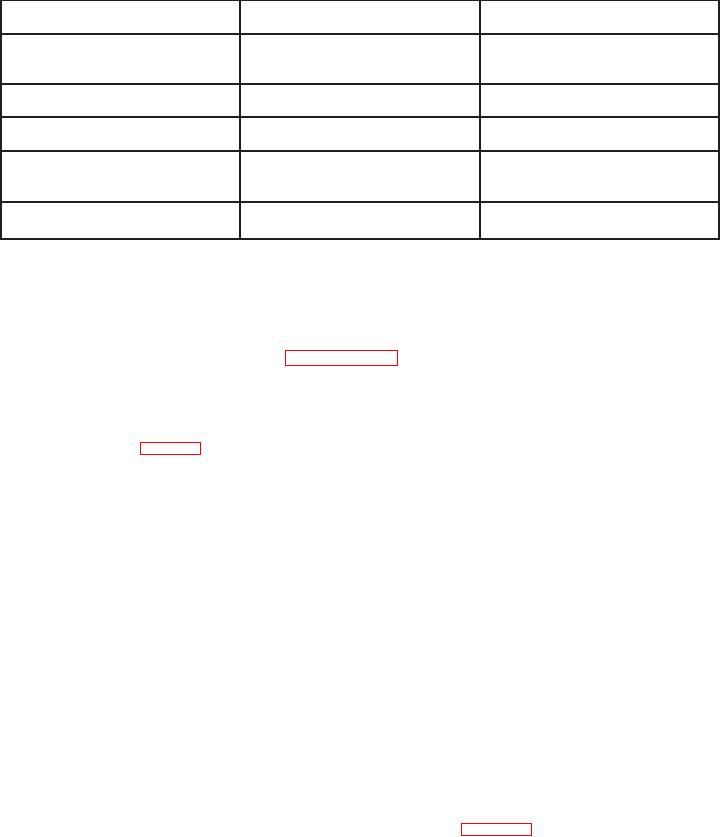

Table 2. Minimum Specifications of Equipment Required

Manufacturer and model

Common name

Minimum use specifications

(part number)

o

ANGLE PLATE

Range:

90

Taft-Pierce, Model 9193

Accuracy: Square within

0.0008 in/8 in.

GAGE BLOCKS

Range:

0.050 to 4 in.

(7901961)

Accuracy: 0.0005 in.

PRECISION LEVEL

Range:

N/A

(7916928)

Accuracy: 30 arc-sec

SINE PLATE

Size:

10 in

Robbins Engineering, Model

o

Range:

0 to 45

A10

Accuracy: 30 sec (angle)

SURFACE PLATE

Range:

18" x 24"

DoAll Mfg. Co., 18 x 24-in.

Accuracy: N/A

(7900123)

CALIBRATION PROCESS

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the calibration

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this procedure. Additional

maintenance information is contained in the manufacturer's manual for this TI.

d. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

a. Allow TI and test equipment 4 hours to stabilize at ambient temperature.

b. Inspect TI top and bottom reference surfaces for defects and cleanliness. Repair and

clean as necessary.

c. Use precision level to level surface plate within 30 sec-arc along length and width of

surface plate.

8. Angle Indication Calibration

a. Performance Check

(1) Setup equipment on surface plate as shown in figure 1. Place TI on the base,

bubble level in the lower left corner.