TB 9-5220-211-50

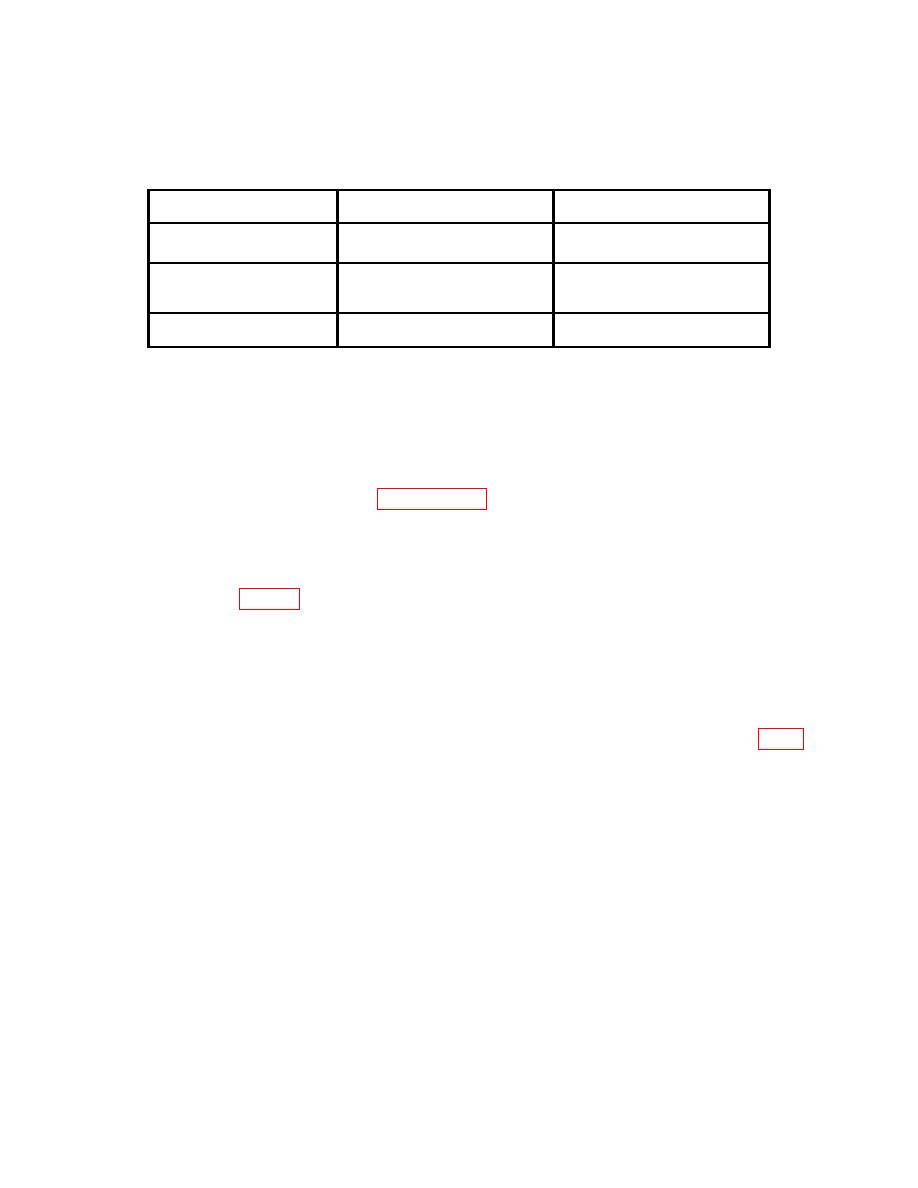

Manufacturer and model

Common name

Minimum use specifications

(part number)

GAGE BLOCK SET

Range: 1.2 to 6.3 in

Grade 1, Class I (79010765)

Accuracy: 0.000012 in

HEIGHT GAGE

Range: 1.2 to 6.3 in

Federal Products Corp.,

Electro-Check, Model 230P-121

Accuracy: 0.00001 in

(7904823)

SURFACE PLATE

DoAll Mfg. Co., 18 x 24-in.

Accuracy: 0.000050 in

(7900123)

6. Preliminary Instructions

process. Personnel should become familiar with the entire bulletin before beginning the

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the results of each test and whenever the test

requirement is not met, take corrective action before continuing with the calibration.

two stacks of gage blocks on surface plate. The two stacks of gage blocks must be the same

height as the two rolls of the TI, within the measuring range of the height gage (fig 1).

Allow all equipment to thermally stabilize for at least 12 hours.

NOTE

The approximate height of the gage block buildup can be

determined prior to thermal stabilization by alternately

moving the height gage stylus over the sine plate rolls and the

corresponding gage block buildup. After the items have

thermally stabilized, they must not be handled with the hands.

Use forceps for handling the TI and gage blocks.