TB 9-6625-2368-24

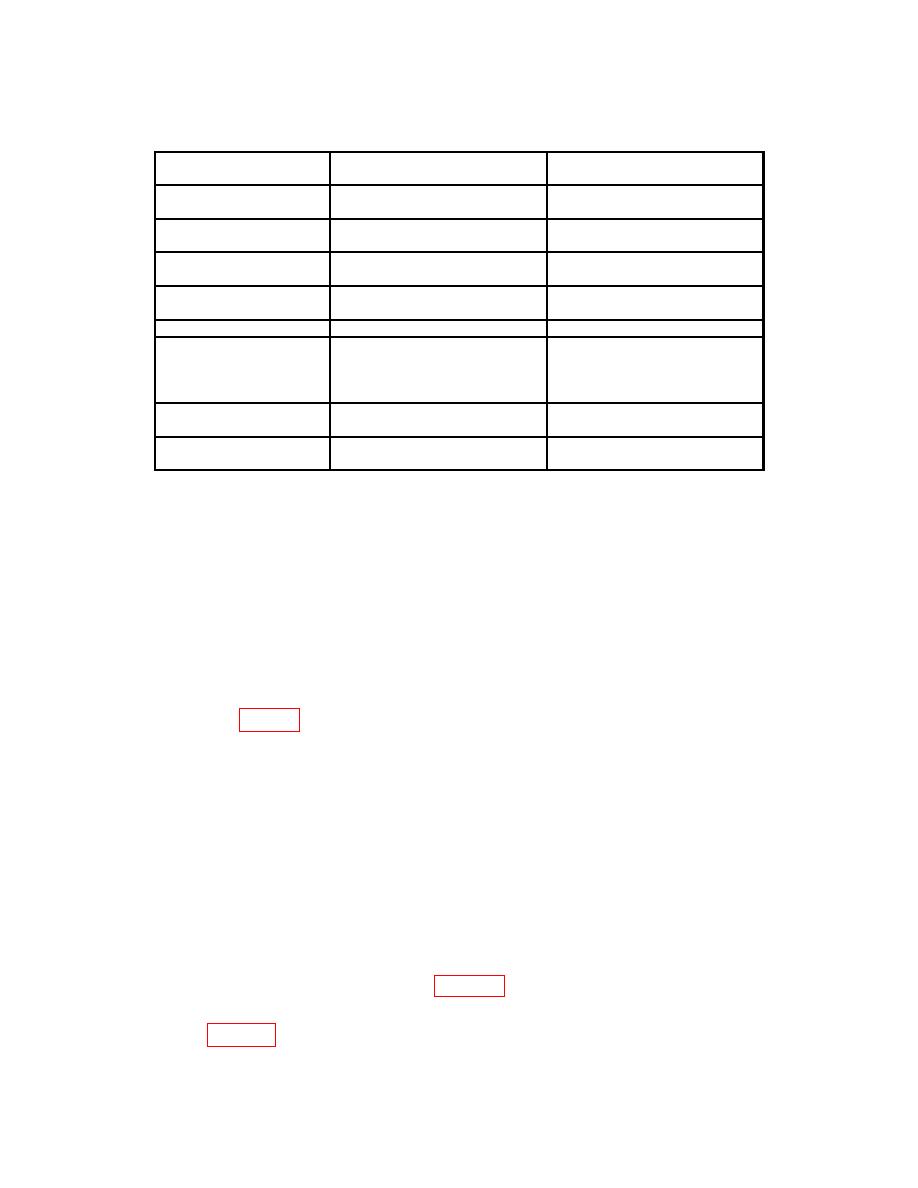

Manufacturer and model

Common name

Minimum use specifications

(part number)

CALIBRATION ARM 6"

Accuracy:

Avans' Machine & Tool, Model

1

13613520

CALIBRATION ARM 48" Accuracy:1

Avans' Machine & Tool, Model

13613522

HANGER ASSEMBLY

Range: 2 lb

Henry Troemner LLC DBA

Accuracy:

Hengar CO, Model 9482T

1

HANGER ASSEMBLY

Range: 5 lb

AMCOM, Model 7916812

Accuracy:1

JACK SET

Range: 0 500 lb

(13613500)

Range: 0 to 1000 V

Agilent, Model 3458A

Accuracy: ( (ppm of reading +

ppm of range)

Range: 100 mV

TIME/FREQUENCY

Capability: latitude/longitude

Datum, Model ET6000-75

WORKSTATION

m/s

(13589305)

2

WEIGHT SET

Range: 0-250 lb

AMCOM, Model 7913046

Accuracy:

1

Combined accuracy of weight set and weight balance and gravity 0.125% (0.13%).

1

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the calibration

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this procedure. Additional

maintenance information is contained in the manufacturer's manual for this TI.

d. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

a. Verify that TI is clean and free from defects that would impair operation.

b. Insure that equipment has been allowed to stabilize at ambient temperature.

c. Position mounting plate on a stable and rigid work surface and secure with bolts.

illustrated in figure 1.