TB 9-6635-208-50

(2) Rotate the TI clockwise until knot of nylon string is on side of pulley opposite

weight and slightly below center of pulley. Observe indication on TI.

(3) Rotate the TI counterclockwise until knot of nylon string is again opposite

weight and slightly below center of pulley. Observe indication on TI.

(4) If the indications observed in (2) and (3) above are not the same, perform b

below.

b. Adjustment

(1) Remove the bezel and crystal assembly by prying gently.

(2) Repeat a(l) through (3) above and adjust position of index to obtain equal

indications in both directions (R).

9. Range

a. Performance Check

(1) Using weight and pulley combinations as specified in tables 4, 5, and 6 for

appropriate range of the TI, check the TI in both directions.

(2) Indications obtained on the TI should be within the tolerances specified in the

appropriate table.

b. Adjustment. If necessary prepare a correction chart for TI, delineating any

corrections to be applied to obtained readings.

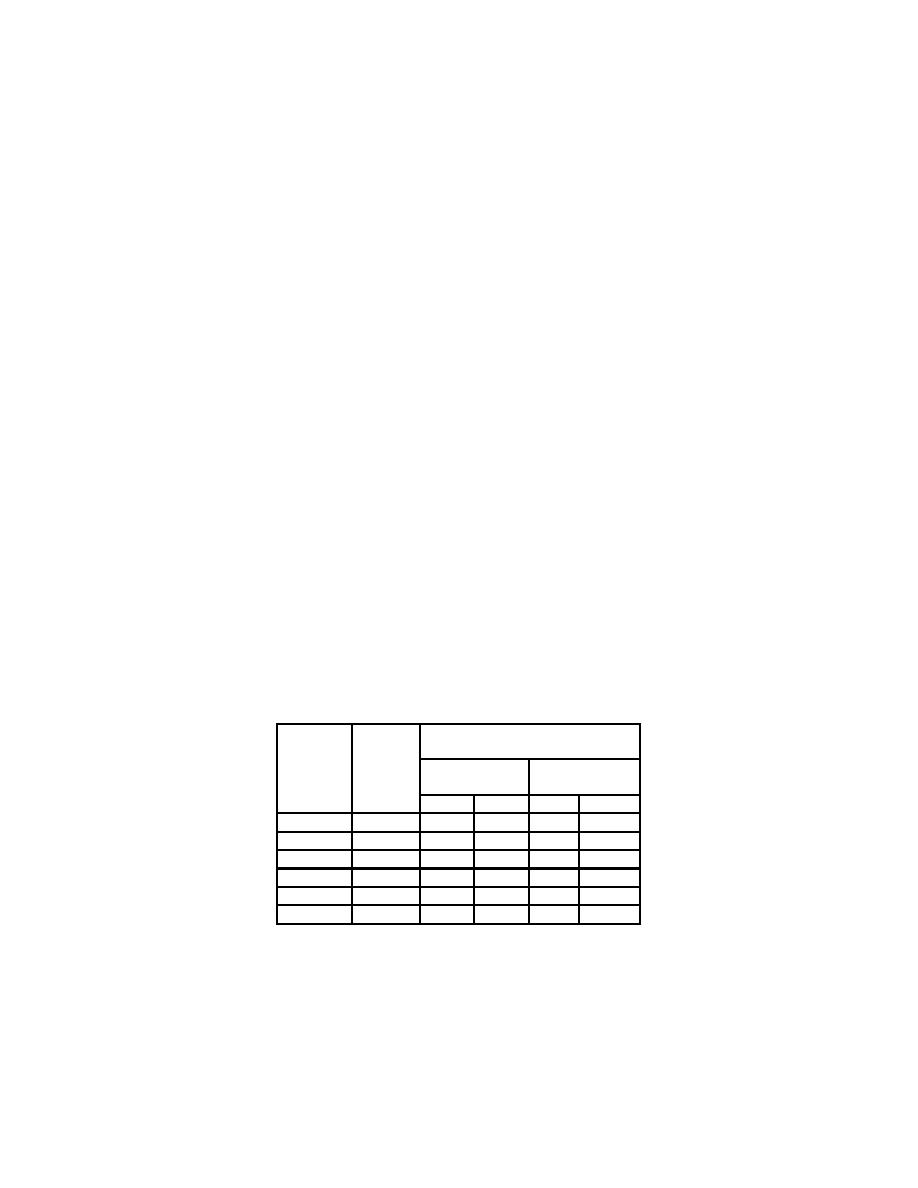

Table 4. Range Check (0 to 40 Inch-Ounce, 4-Inch Pulley).

Test instrument

Required

5% of full

2% of full

scale

scale

Cardinal

weight

point

(oz)

Min

Max

Min

Max

6

3

4

8

5

7

12

6

10

14

11

13

18

9

16

20

17

19

24

12

22

26

23

25

30

15

28

32

29

31

36

18

34

38

35

37

5