TB 9-4931-700-50

(t) Repeat technique of (n) through (r) above for A12A4. Replace A12A4 in

TI.

(13) Repeat a(1) through (4) above.

9. Error Measurement

a. Performance Check

(1) Insert adapter (B1) between TI and autotransformer (A2) and connect

OUTPUT and SENSE terminals to ratio transformer (A8), using hook-up wire (B9).

Monitor output of ratio transformer, using ac/dc voltmeter (A1) and hook-up wire.

(2) Position TI controls as listed in (a) through (f) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage controls to obtain indication of 1.000000 v

(c) Adjust FREQUENCY control to obtain FREQ scale indication of 1.

(d) Press FREQUENCY RANGE X1K pushbutton.

(e) Press ERROR RANGE 0 pushbutton.

(f) Press SENSE REMOTE pushbutton.

(3) Set ratio transformer dials to 1.000000 and record ac/dc voltmeter indication.

(4) Press ERROR RANGE X1 pushbutton and adjust ERROR MEASUREMENT

control to obtain an indication of 0 (zero) on % ERROR scale. If ac/dc voltmeter does not

indicate within 0.00017 V of value recorded in (3) above, perform b below.

(5) Repeat technique of (3) and (4) above, using setting and indications listed in

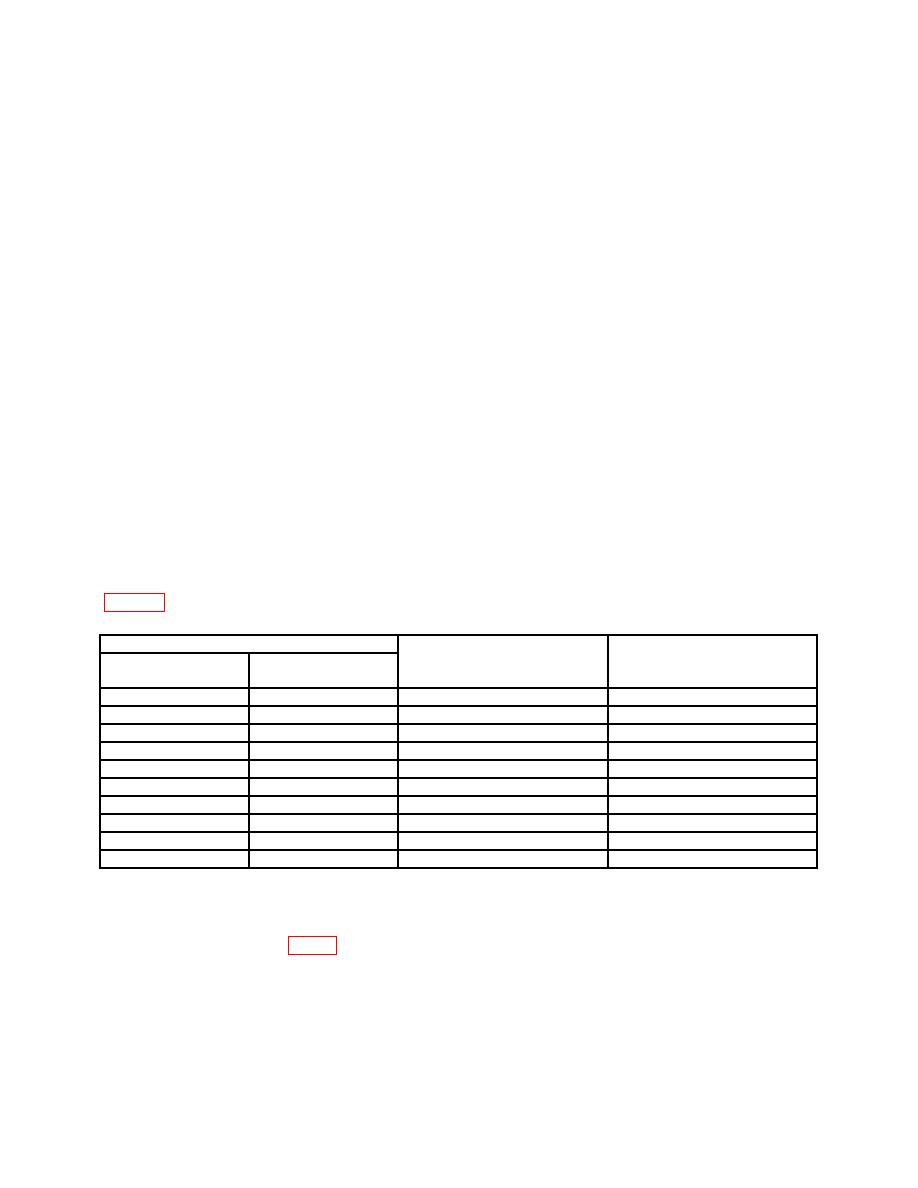

Test Instrument

ERROR RANGE

% ERROR

Ration Transformer

Ac/dc Voltmeter

Setting

Scale Setting

Setting

Indication (V)

Value of 9a(3) above 0.00017

X1

-3

.970874

Value of 9a(3) above 0.00017

X1

-2

.980392

Value of 9a(3) above 0.00017

X1

-1

.990099

Value of 9a(3) above 0.00017

X1

01

1.000000

Value of 9a(3) above 0.00017

X1

+3

1.030929

Value of 9a(3) above 0.00017

X1

+2

1.020408

Value of 9a(3) above 0.00017

X1

+1

1.010101

Value of 9a(3) above 0.000035

X.1

01

1.000000

Value of 9a(3) above 0.000035

X.1

-3

.997009

Value of 9a(3) above 0.000035

X.1

+3

1.003009

1Establish

a new 1-volt reference as in 9a(3) above.

b. Adjustments

(1) Set A1A4S1 (fig. 2) to +9.9 V position.

NOTE

Overload lamp illuminates.