TB 9-4935-558-40

Table 2. Minimum Specifications of Equipment Required

Manufacturer and model

Common name

Minimum use specifications

(part number)

(SKD4850-107)

2.1515 .001 in.

P/O SK-A-4850-103

WEIGHT

(8598963)

94 1 lb.

P/O 10-10525

WEIGHT TABLE

(SKA4850-104)

1 .25 lb.

PRELIMINARY OPERATIONS

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the calibration

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this procedure.

d. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

a. Release any applied load on slide of TI force gage.

b. Stand the TI in an upright position on the calibration stand. Tighten the adjusting

the pointer on the gage just begins to deflect. Loosen adjusting screw slider until all the

load on the force gage is removed. Tap the slider with finger. The pointer of the force gage

should move with each finger tap if all the load is removed.

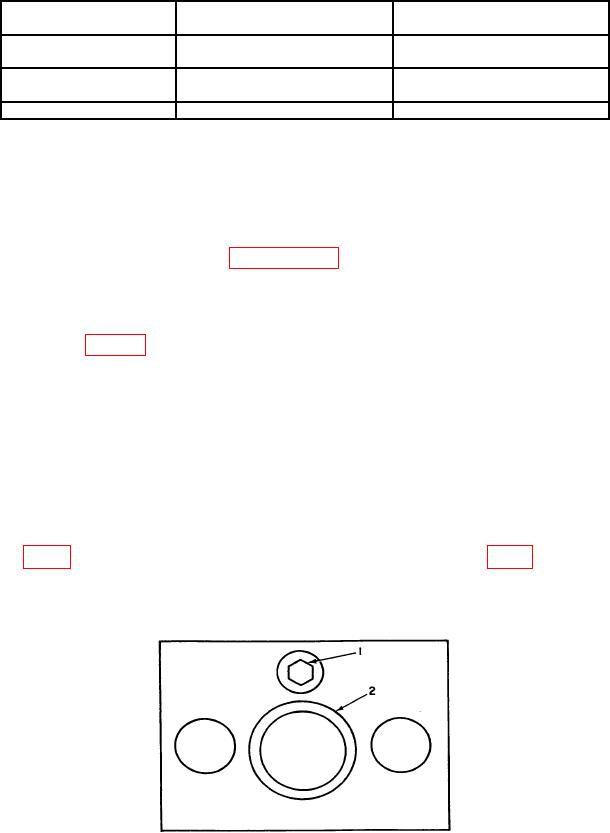

1 - Adjusting screw

2 - Slider

Figure 1. Top view test instrument.