TB 9-5120-212-24

12. Torque

a. Performance Check

WARNING

Friction brake must be adjusted to hold 1200 ft-lbs applied

torque when pressure is released from T-handle.

(1) Check friction brake by carefully applying torque in small increments and

ensuring that friction brake holds up to 1200 ft-lbs. If friction brake does not hold, tighten

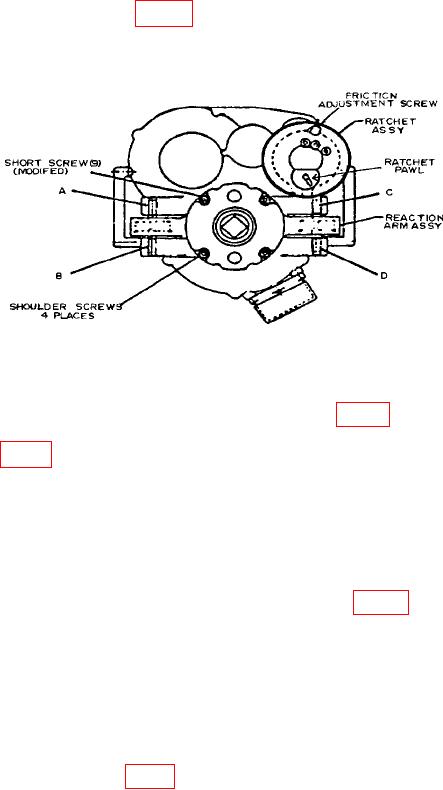

FRICTION ADJUSTMENT SCREW (fig. 4) to increase friction. Do not over-tighten

because the friction brake must be overcome to back off torque that has been applied.

Maximum torque needed to overcome brake should not exceed 75 ft-lbs.

Figure 4. Torque Wrench - Adjustment Locations.

CAUTION

Do not attempt to reverse the RATCHET PAWL (fig. 4) with

torque applied. When torque is applied cw with RATCHET

PAWL (fig. 4) in nut-on position, the T-handle must be turned

ccw against resistance of the friction brake to release the

applied torque.

NOTE

Two ratchets are used on this TI, one on the torque wrench and

one on the T-handle. Operation of the T-handle ratchet is

obvious. The torque wrench ratchet operates in conjunction

with the friction brake. The RATCHET PAWL (fig. 4) is

labeled nut-on for cw torque and nut-off for ccw torque.

(2) Exercise TI and torque cell scale three times in cw direction.

(3) Press the F4 key on the force/torque indicator until →0← soft key is displayed.

Press the →0← soft key to zero force/torque indicator.

(4) Check cw and ccw balance of TI as follows:

(a) Set RATCHET PAWL (fig. 4) to nut-on position.