TB 9-5220-212-40

NOTE

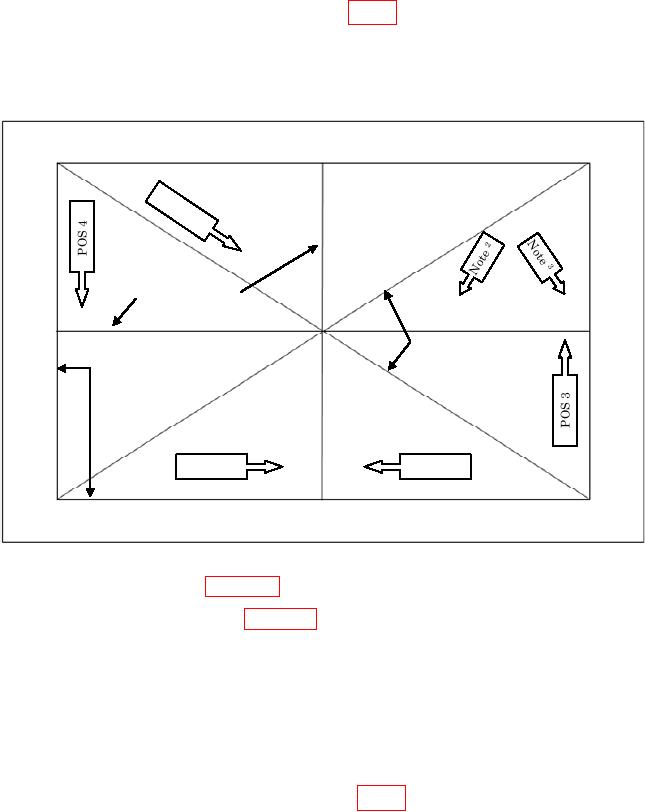

Make certain that end stations of perimeter lines tie in with

end stations of diagonals and that end stations of centerlines

tie in with midpoints of perimeter lines as closely as possible.

(4) Place autocollimator at position 1 (fig. 1).

NOTE

It may not be possible to position autocollimator exactly as

shown because of size.

NORTH 1

No

te

3

CENTERLINES

EAST

WEST

DIAGONAL LINES

PERIMITER LINES 4

POS 1

POS 2

SOUTH

1 North

will be designated by manufacturer's label.

2 For

small TI surfaces, position autocollimator in POS 2. (This footnote does not apply when using

differential electronic level in Section IV.)

3 Position of autocollimator for small TI's for WEST-EAST CENTERLINE. (This footnote does not apply when

using differential electronic level in Section IV.)

4 The PERIMETER LINES should be a minimum 1 inch in from edge if length of diagonal is 48 inches or less

and 1-1/2 inches in from edge if diagonal is over 48 inches.

Figure 1. Granite Surface Plate - Calibration Setup.

(5) Lay straight edge immediately adjacent to line that is to be calibrated and clamp

to TI.

NOTE

Each line is designated by number

corresponding

to

autocollimator position number (fig. 1).

(6) Mount mirror on carriage and position adjacent to straight edge at first station

to be measured.

5