TB 9-6625-2326-24

provide a four to-one ratio between the standard and TI. Where the four-to-one ration

cannot be met, the actual accuracy of the equipment selected is shown in parenthesis.

paragraph 4 above and are used in this calibration procedure. When necessary, these items

may be substituted by equivalent items, unless specifically prohibited.

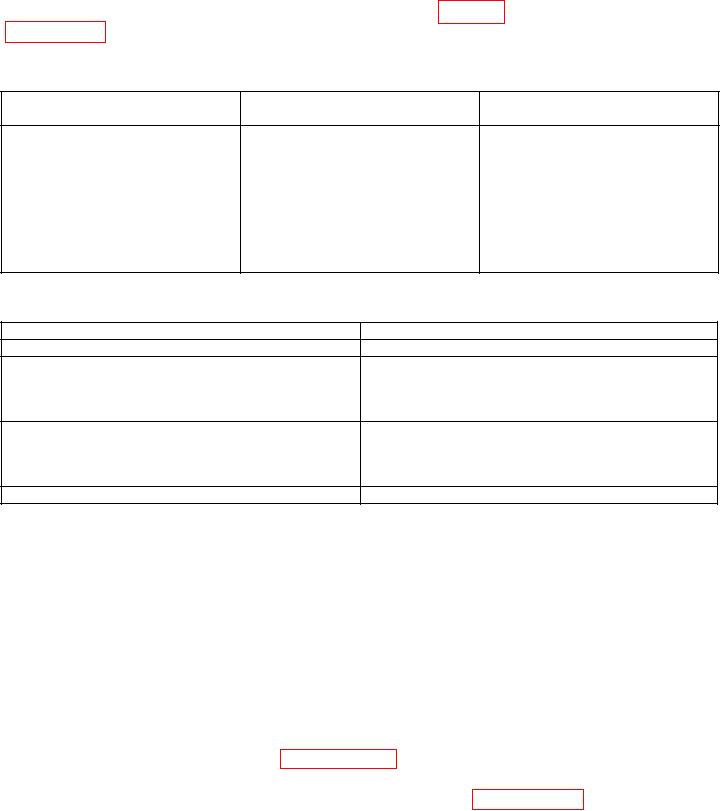

Table 2. Minimum Specifications of Equipment Required

Manufacturer and model

Common name

Minimum use specifications

(part number)

CALIBRATOR

Range: 0.2 V dc to 200 V dc

Fluke, Model 5720A (5720A) (p/o

Accuracy: 0.25%

MIS-35947); w amplifier, Fluke

5725A/AR (5725A/AR)

Range: 0.2 V ac to 200 V ac

Accuracy: 0.75%

Frequency: 500 Hz

A

Range: 0 to 20 M

ccuracy: 0.25%

Table 3. Accessories Required

Common name

Description (part number)

1

CONTROLLER

Polywell (MIS-45854)

SPORT or MSD 1

Miltope, AN/PSM-95

Miltope, AN/PSM-95A

(To be provided by customer for calibration of DM224

(Turned in with TI if required)

if Polywell Controller w/preinstalled calibration

software not available.)

SPORT/MSD DMM

Calibration software

Maintenance Disk 1

(provided to teams by PM-TMDE)

(Provides calibration software routine for use on

SPORT/MSD.)

TEST LEAD CONNECTOR 2

Type 311 cable

1Verify

you have latest calibration software updates and other necessary information from USATA homepage at

TB 9-6625-2326-24 folder location.

2To be supplied with TI.

CALIBRATION PROCESS FOR DM224

(UTILIZING POLYWELL CONTROLLER)

NOTE

Use of this section of the TB requires use of the Polywell

Controller (MIS-45854) with the DM224 Calibration Software

pre-installed. If you do not have access to this controller, you

will need to perform SECTION IV. Be advised that this pre-

installed software is unique and not to be confused with the

SPORT/MSD DMM Maintenance Disk that is used in SECTION IV.