TB 9-6625-2802-35

cable assembly (B2) to digital voltmeter (A2) so as to

Army Calibration System). When the TI cannot be

adjusted within tolerance, annotate and affix DA Form

2417 (Unserviceable Equipment) tag.

b. Adjustments. No adjustments can be made.

c. If the TI can be used for certain maintenance

14. Final Procedure.

functions, even though not meeting all calibration

specifications, affix DA Label 163 (Limited or Special

a. Deenergize and disconnect all equipment and

Calibration) to identify equipment which can be used for

reinstall protective cover on TI.

some specific procedures.

b. In accordance with TM 38-750, annotate and

affix DA Label 80 (U.S.

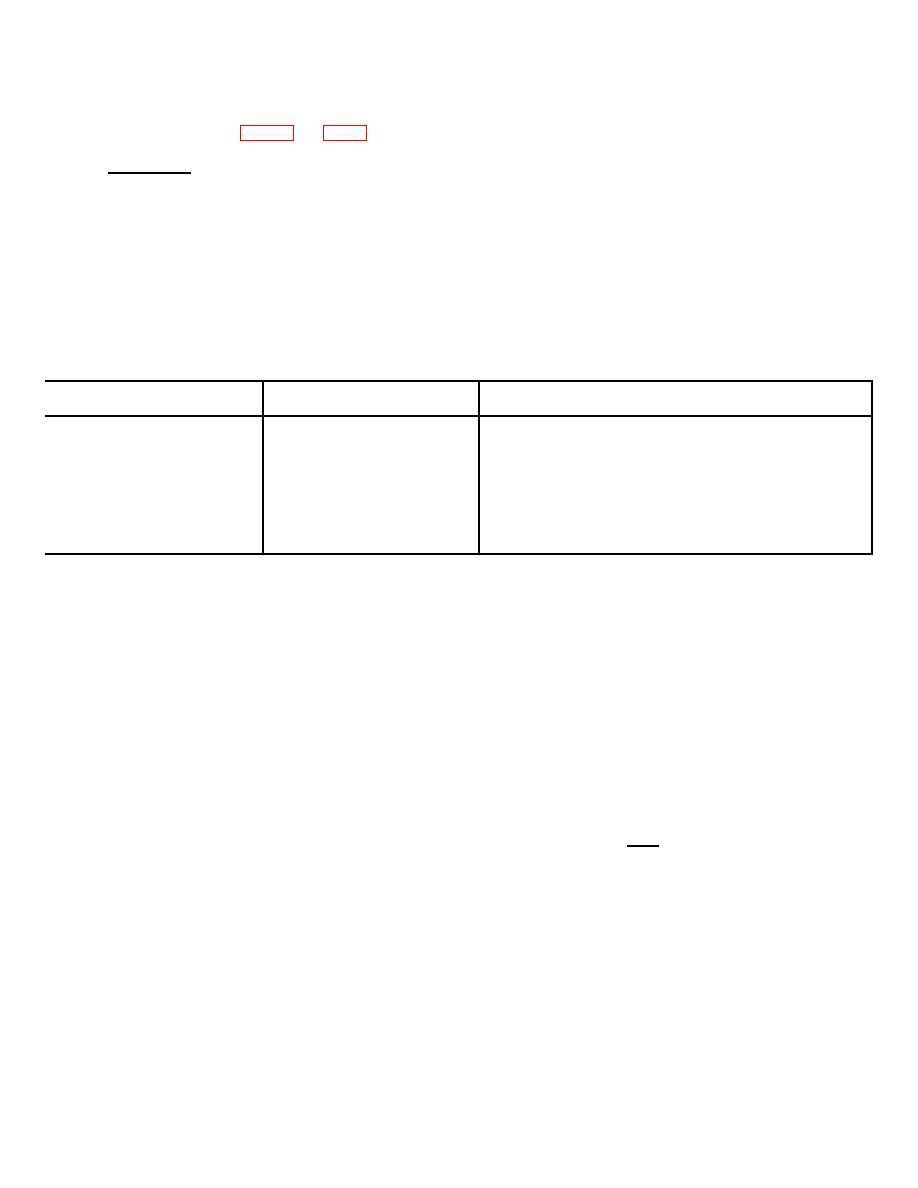

Table 4. Power Supply Voltage Checks

Source

Minimum

Nominal

Maximum

Q10 emitter

+35.7

+36.5

+37.3

CR6 cathode

-0.6

-0.7

-0.8

CR13 anode

-6.06

-6.19

-6.32

CR14 anode

-22.1

-23.1

-24.1

Q13 emitter

-30.1

-31.6

-33.1

SECTION V

CALIBRATION PROCESS, OSCILLOGRAPHIC RECORDER

(4)Position pens on center lines numbered 1

NOTE

and 2.

All performance checks are made with

(5) Set INPUT to OPR and run about 100 mm

both preamplifiers installed.

(four divisions) of paper.

15. Paper Speeds.

(6) Measure distance between first and

eleventh time mark.

Chart speed

a. Performance Check.

accuracy is number of marks multiplied by

chart rate (1 mm = 0.0394 in.). The

(1) Connect time mark generator (A7) to

distance measured should be accurate to

either preamplifier input using cable (B3)

+0.05% and the accuracy can be

and adaptor (B1). Set generator to 1 SEC.

calculated from the following formula:

(2) Turn LINE switch to ON and preamplifier

Ddiff

INPUT to ZERO.

Error = DT X 100 DT

(3) Set CHART SPEED to 1 mm/SEC.

10