TB 9-6695-242-24

usage accessories issued as indicated in paragraph 4 above, and are not listed in this

calibration procedure.

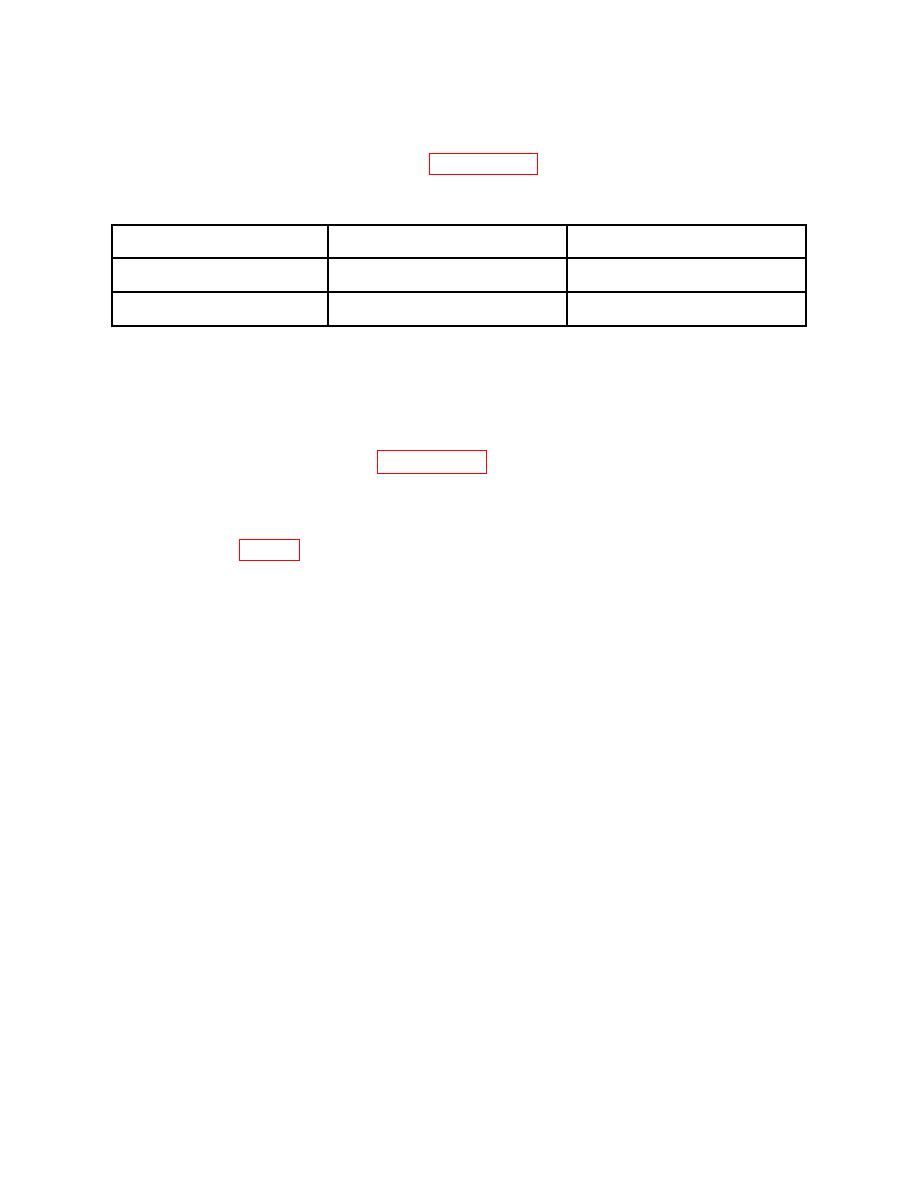

Manufacturer and model

Common name

Minimum use specifications

(part number)

LOAD CELL INDICATOR

Range: 175 to 20,400 lbs

HBM, Model MGCplus (13589298)

Accuracy: 0.05% of reading

LOAD CELL

Range: 900 to 20,400 lbs

Revere Corporation, USP1-20B

1

(MIS-26331TY3)

Accuracy: 0.25% FS

1Limited

deployment item.

6. Preliminary Instructions

process. Personnel should become familiar with the entire bulletin before beginning the

calibration.

b. Items of equipment used in this procedure are referenced within the text by common

name as listed in table 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with the calibration.

Adjustments required to calibrate some models of the TI are included in this procedure.

Additional maintenance information is contained in the manufacturer's manual for this TI.

d. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

HIGH VOLTAGE is used or exposed during the performance of

this calibration.

DEATH ON CONTACT may result if

personnel fail to observe safety precautions.

REDUCE

OUTPUT(S) to minimum after each step within the

performance check where applicable.

a. Visually inspect TI for any damage that will affect measuring accuracy.

b. Check that TI clevis pivots freely and easily on shackle.

c. Tighten two locking screws on back of TI.

CAUTION

Locking screws must be tight to prevent damage to gage

movement.

d. Adjust zero-adjusting screw (located in slot on side of TI) until pointer indicates zero.