TB 9-6695-301-50

7. Equipment Setup

a. Verify TI is clean and free from defects that would impair its operation.

b. Allow equipment to stabilize to ambient temperature.

Calculate torque for cardinal points listed in table 4 for each TI. Use CALCULATED

TORQUE formula shown after table 3.

NOTE

If the arm lengths are correct to: (.02-in. for 40-in. arm); (.005-

in. for 10-in. arm); and (.0015-in. for 2.5-in. arm); then nominal

values may be used for length and the equation becomes:

T = Nominal length x weight corrected for local gravity.

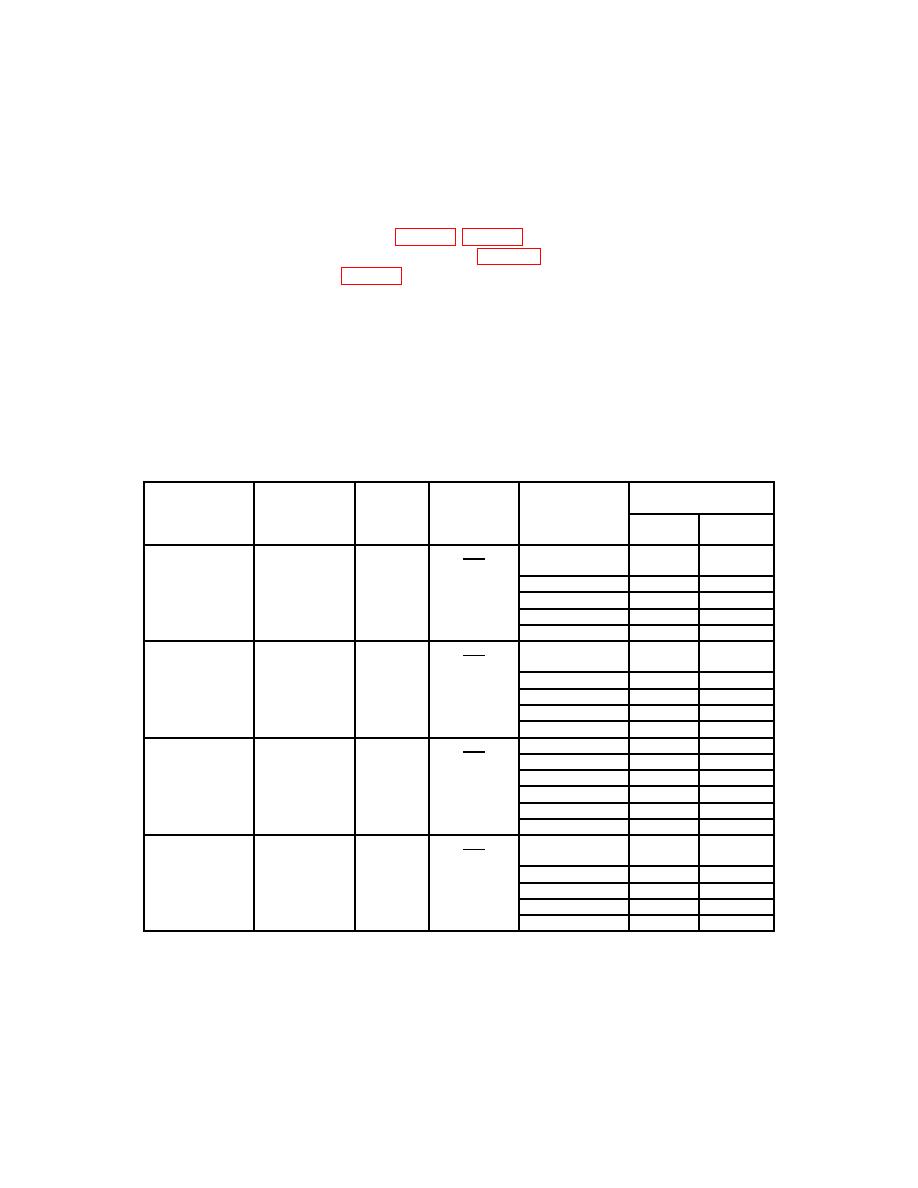

Test

Actual

Tolerance range

instrument

Weight

weight1

Calculated2

Min

Max

range

calibrator

(lbs)

(lbs)

torque

(-0.5%)

(+0.5%)

Model

lbs

0 to 60 in-lb

60 STPI

5

0 to 5 ft-lb

(2.5-in.

10

radius)

15

20

Full scale

24

Model

lbs

0 to 20 ft-lb

2000 STPI

5

0 to 240 in-lb

(10-in.

10

radius)

15

20

Full scale

24

Model

lbs

0 to 100 ft-lb

2000 STPI

24

0 to 1200 in-lb

(10-in.

48

radius)

72

96

Full scale

120

Model

lbs

0 to 500 ft-lb

STPI

30

(40-in.

60

radius)

90

120

Full scale

150

See footnotes at end of table.