TB 9-6625-1962-24

8. Dc Volts

a. Performance Check

(1) Connect lead between TI COM INPUT connector and ground post connector on

indicator oscilloscope.

(2) Connect calibrator OUTPUT V A HI and LO to TI INPUT HIGH and COM terminals.

(3) Set MODE/RANGE switch to DC VOLTS 2V.

(4) Adjust calibrator output to obtain indicator oscilloscope readout display of 2.000

volts. If calibrator does not indicate between 1.997 and 2.003 volts, perform b below.

(5) Adjust calibrator to obtain indicator oscilloscope readout display of -2.000 volts.

If calibrator does not indicate between -1.997 and -2.003 volts, perform b below.

(7) Repeat technique of (3) through (5) above for MODE/RANGE switch positions

listed in table 3. Calibrator indications will be within limits specified.

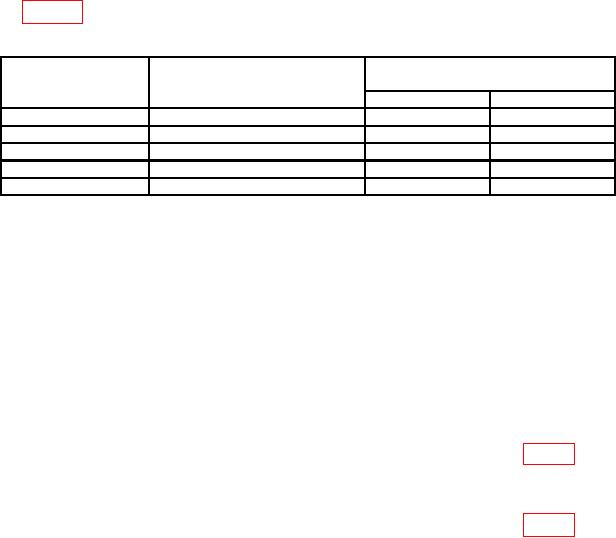

Table 3. Dc Volts

Indicator oscilloscope

Calibrator indications

Test instrument

MODE/RANGE

readout display

(V)

switch positions

indications

Min

Max

DC VOLTS 20V

2.000

1.99

2.01

DC VOLTS 20V

20.00

19.97

20.03

DC VOLTS 200V

20.00

19.9

20.1

DC VOLTS 200V

200.0

199.7

200.3

DC VOLTS 1kV

1000.0

998

1002

b. Adjustments

NOTE

For adjustments on model 7D13A, use calibration fixture

(extender) for access to adjustments.

(1) Adjust calibrator for 2.0000 volts.

(2) Connect frequency counter between TP206 (located near center of circuit board

assembly) and ground. If frequency counter does not indicate between 79.5 and 80.5 kHz,

adjust R203 (located adjacent to TP206) to obtain an indication of 80 kHz. Remove

frequency counter connection.

(3) Adjust R148 GAIN ADJ (7D13) R1003 VOLTS (7D13A) (fig. 1) to obtain

indicator oscilloscope readout display of 2.000 volts (R).

(4) Adjust calibrator for -2.0000 volts.

(5) Adjust R148 GAIN ADJ (7D13) R1003 VOLTS (7D13A) (fig. 1) to obtain

indicator oscilloscope readout display of -2.000 volts.

(6) Repeat (1) and (3) through (5) above for best compromise between positive and

negative 2.000 volts.