TB 9-5885-1892-24

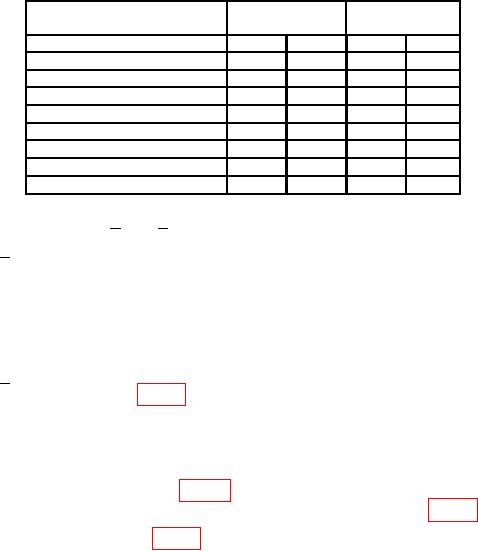

Table 4. Temperature Correction Settings - Continued

Temperature error

Dip switch

Dip switch

C

1

2

A

B

C

D

+0.025 to +0.075

Off

Off

Off

Off

0.025 to

0.075

Off

On

On

On

0.075 to

0.125

On

Off

On

On

0.125 to

0.175

Off

Off

On

On

0.175 to

0.225

On

On

Off

On

0.225 to

0.275

Off

On

Off

On

0.275 to

0.325

On

Off

Off

On

0.325 and less

Off

Off

Off

On

(f) Perform steps 1 and 2 below:

1

Set TI ON/OFF switch to OFF.

CAUTION

Disconnect ac power cable from TI before changing dip switch

settings and reconnect TI ac power cable after changing dip

switch settings.

2 Set dip switch 1, A and B to on and dip switch 2, C and D to on, then

loosely replace large cover plate (fig. 2).

10. Final Procedure

a. Deenergize and disconnect all equipment.

b. Remove TI large cover plate (fig. 2), place TARGET SELECTOR SWITCH back in

original position and tighten TARGET SELECTOR SWITCH screws (fig. 7).

c. Install TI large cover plate (fig. 2) and four screws.

d. Using cotton tip applicator soaked with paste removal solvent, clean thermal

conductive paste from TI heater plate surface, MRT target housing, and thermocouple

wires. Remove solvent residue using dry cotton tip applicator.

NOTE

If residue is severe, a cotton tip applicator soaked in contact

cleaner (Krylon No. 1333) may be used, then remove solvent

residue with a dry cotton tip applicator.

e. Stow all cables in straps provided, reinstall shroud and reinstall TI in transit case.

f. Annotate and affix DA label/form in accordance with TB 750-25.

13/(14 Blank)