TB 9-6685-316-50

WARNING

This procedure involves pressures that could be hazardous to

personnel. Exercise due caution at all times and wear safety

glasses while performing checks.

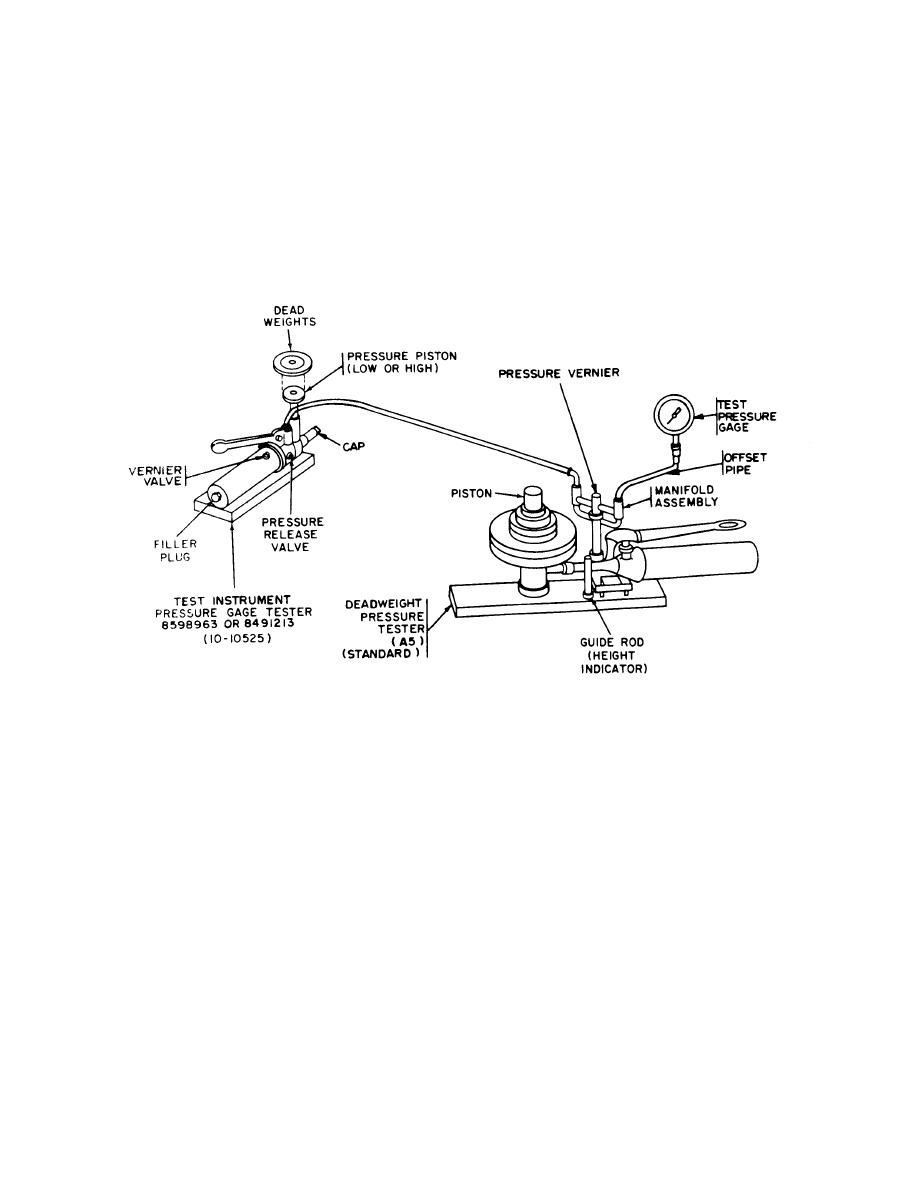

(2) Level TI and deadweight pressure tester (A5) (standard) using level (B1).

(3) Install low-range pistons in cylinders of both units and place 95-psi weights

(supplied with pressure gage testers) on low-range piston of n and standard.

CAUTION

Continuously rotate pistons and weights in TI or standard

cylinder housings whenever pistons am inserted or removed

from housings or when applying pressure to prevent scoring

or sticking in housing and damaging the piston guide and

cylinder.

(4) Apply pressure to equipment setup, using handpump on TI and/or standard

until bottom surface of either weight table is raised approximately 1/4 inch above either

be TI or standard cylinder homing.

(5) Visually inspect equipment for leakage.

6