TB 9-6685-316-50

(14) At the nominal pressure of 1800 psi, if the dP of equation 1 above is positive,

add 1/10 of weight calculated in equation 2 above to the standard instead of the

instructions of (7) above.

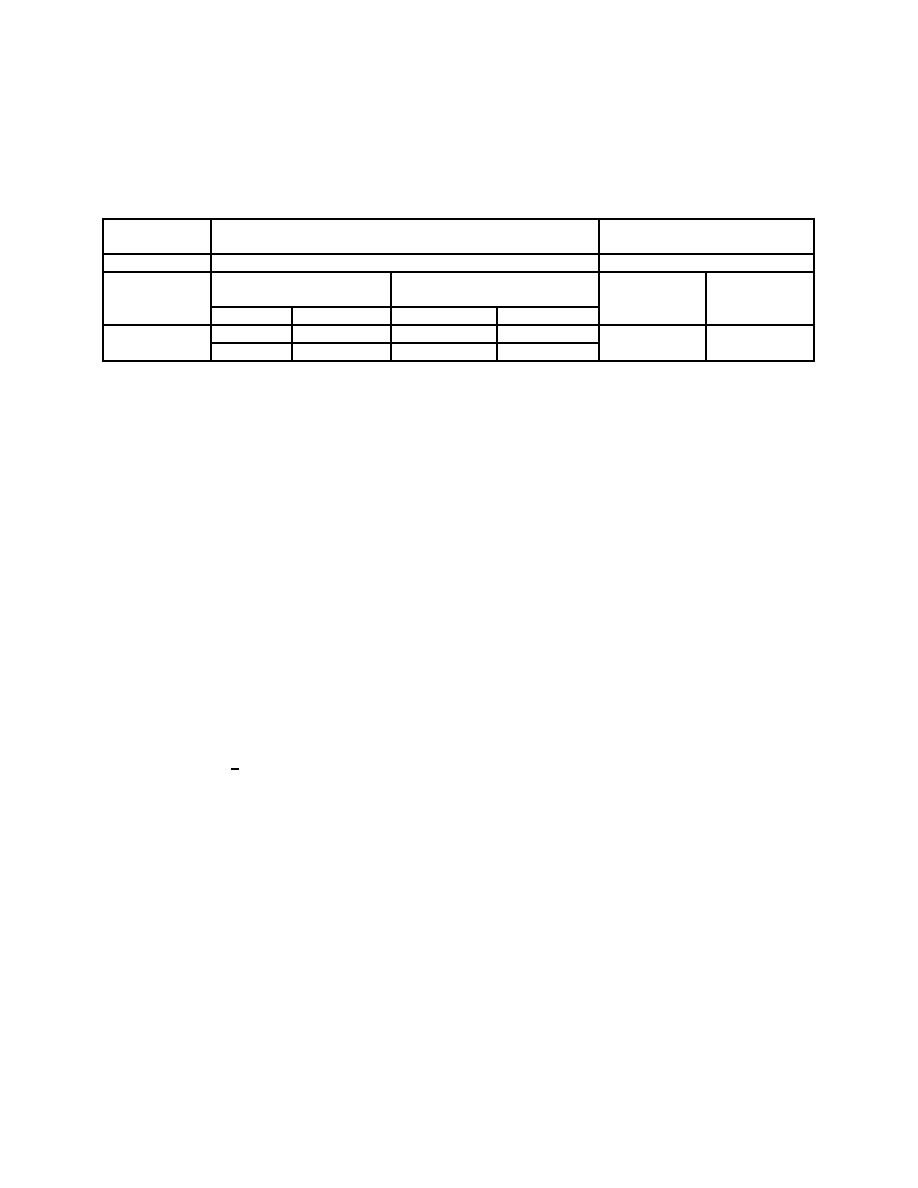

Nominal

Weight combination test instrument

Calibration

pressure (psi)

and standard, including pistons

weight (oz)

100

1-95

1/8 And 1/32

Low-range piston

High-range piston

(Standard)

Test

test instrument

(standard)

floating

instrument

Qty

Press. Unit

Qty

Press. Unit

(oz)

floating (oz)

1800

1

956

1

950

1/4 and 1/32

2, 1/2 and 1/4

17

100

4

200

(15) Install high-range pistons in cylinder housings of TI and standard.

(16) Install 0-10,000 psi pressure gage.

NOTE

When using the high-range piston in both the standard and

TI the reference line of the standard is 6.09 inches above the

reference line of the TI. This is equivalent to 0.1936 psi. A

mass of 1/16 oz must be placed an the TI to compensate for

pressure developed by the fluid head.

(17) Place the 475-psi and nine of the 500-psi weights supplied with the 71 on the

TI piston.

(18) Place the 950-psi and four of the 1000-psi weights supplied with the standard

on the standard piston.

(19) Compute the deviation of the developed pressure from the nominal pressure

of 5000 psi from the Report of Calibration furnished with the standard, using the

following equation:

Equation 3.

dP = 5000 - PR g

gc

Where: dP = difference between nominal pressure and developed pressure (psi).

5000 = nominal pressure (psi).

PR = developed pressure (psi) from Report of Calibration furnished with the standard. gc = local gravity

(furnished with Report of Calibration).

g = 980.665 or 980.217 cm/sec2 (design gravity of piston and cylinder combination).

(20) If dP of equation 3 is positive (+), compute the additional weight required on

the standard to obtain a reference pressure from the equation:

Equation 4.

W = (dP)(0.01)

where: W = weight (lb) to be added to standard to obtain a reference pressure (using avoirdupois weight

set (A1), to the nearest nominal weights combination).

dP = difference between nominal and developed pressure from equation 3 above.

0.01 = nominal piston area of standard (in.2).

9