TB 9-6685-316-50

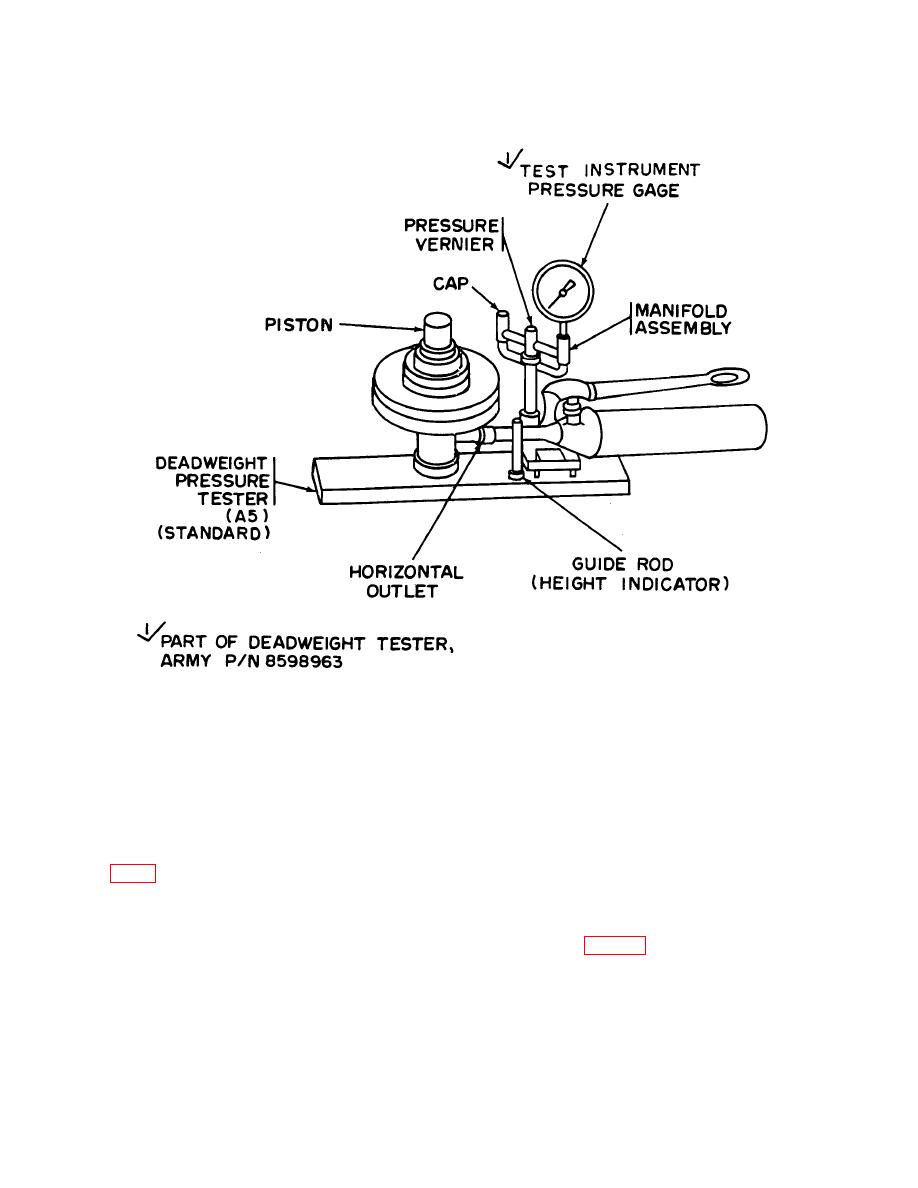

(2) Place four of the 5-psi weights on the piston to obtain a nominal pressure of

25 psi. Use weight calibration specified in the Report of Calibration furnished with the

standard.

(3) Determine pressure developed value from the Report of Calibration

furnished with the standard and apply pressure to equipment setup, manually rotating

weights clockwise until bottom surface of weight table is 1/4 inch above cylinder

(balanced and floating). If necessary, obtain exact balance using pressure vernier valve

(4) Tap face of gage lightly. If gage does not indicate Pressure developed by

weight combination from the Report of Calibration 0.4 psi, perform b below.

(5) Repeat (2) through (4) above for values listed in table 7. If TI pressure gage

does not indicate a value equal to the Pressure Developed value from the Report of

Calibration for each weight combination and within each tolerance indicated, perform b

below.

11