TB 9-6625-1947-35

(16) Set FREQUENCY RANGE switch to X100K and FREQUENCY dial to 10.

and multimeter reading at A2TP2 (fig. 1) between -0.3 and -0.4 V (R).

(17) Repeat (1) through (16) above until frequencies are within specified limits.

a. Performance Check

(1) Connect multimeter to TI UNBAL output using 50 Ω feed-through termination.

(2) Position controls as listed in (a) through (c) below:

(a) FREQUENCY RANGE switch to X1K.

(b) FREQUENCY dial to 1.

(c) OUTPUT LEVEL dBm switch to +10.

(3) Adjust AMPLITUDE control for a 0 dBm indication on TI meter. If multimeter

does not indicate between 0.7000 and 0.7142 V rms, perform b below. Record indication as R1.

(4) Adjust AMPLITUDE control for a 1.0 dBm indication on TI meter. Divide

multimeter indications by R1 value recorded in (3) above. If quotient is not between 1.111

and 1.133, perform b (1) through (10) below.

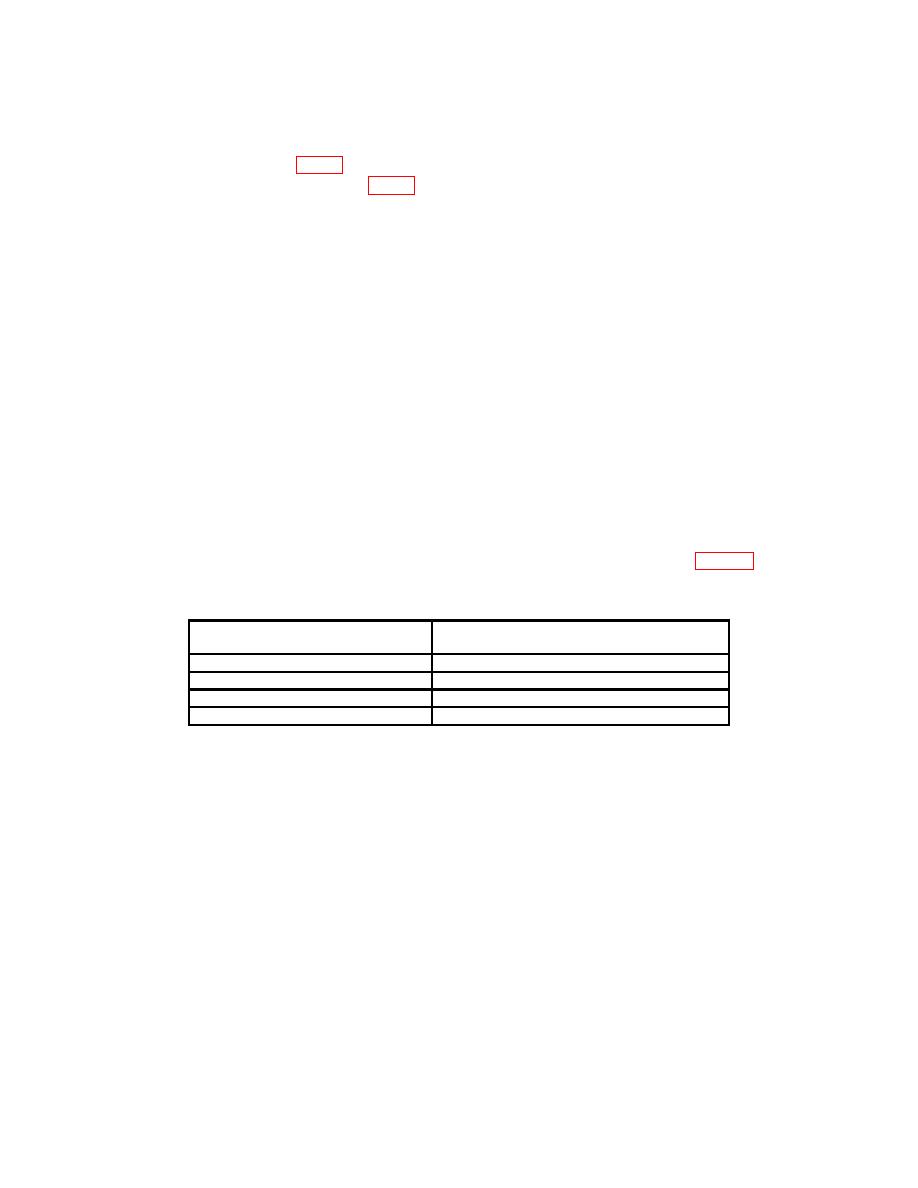

(5) Repeat technique of (4) above, using TI meter indications listed in table 4. If

quotients are not within limits specified, perform b (1) through (10) below.

Test instrument meter indications

Multimeter indications

(dBm)

(V Ac)

+0.8

V ac R1 = 1.085 to 1.107

+0.4

V ac R1 = 1.037 to 1.058

-0.4

V ac R1 = .945 to .965

-0.8

V ac R1 = .800 to .921

(6) Adjust AMPLITUDE control to minimum and disconnect multimeter and

termination from TI.

(7) Connect thermal converter to UNBAL output.

(8) Connect multimeter to thermal converter.

(9) Adjust AMPLITUDE control for a 0 dBm indication on TI meter and record dc

voltage indication on multimeter as R2.

(10) Disconnect thermal converter from TI and connect to calibrator.

(11) Adjust calibrator output until value of R2 is indicated on multimeter. Record

calibrator indication.

(12) Adjust calibrator to +0.5 percent of value recorded in (11) above. Record

multimeter indication as R3.