TB 9-6685-383-40

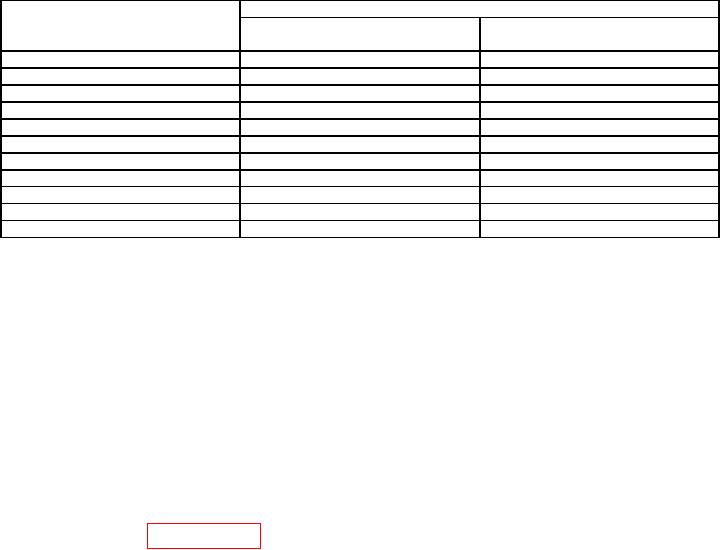

Table 6. Internal/External Pressure.

Permissible Deviation

Nominal applied value as a %

LP* Versions and

of full scale

PC*, HC* and Indicator Versions

External LPE 9400 Sensors

0 % (10% for absolute ranges)

0.025% FS

0.05 % span

20 %

0.025% FS

0.05 % span

40 %

0.025% FS

0.05 % span

60 %

0.025% FS

0.05 % span

80 %

0.025% FS

0.05 % span

100 %

0.025% FS

0.05 % span

80 %

0.025% FS

0.05 % span

60 %

0.025% FS

0.05 % span

40 %

0.025% FS

0.05 % span

20 %

0.025% FS

0.05 % span

0% (10% for absolute ranges)

0.025% FS

0.05 % span

PC* = Pressure Calibrator

HC* = Hydraulic Calibrator

LP* = Low Pressure Calibrator

b. Adjustments

(1) Switch the TI on. Press the following SET UP: down arrow to SETTINGS,

ENTER, down arrow to CALIBRATION and ENTER.

(2) Apply zero pressure and store the zero point. The screen will say click ENTER

key when applied value is stable. If the TI is not zeroed, press F1 CHANGE VALUE and,

using the up/down and left/right arrows, set the zero value. The TI will prompt to Store

Zero Point, F1=Yes, F2 = No.

(3) Close the vent valve and apply full-scale pressure using the key pad. Repeat

step (2) above, except use Full Scale pressure.

(4) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit CALIBRATION and SETUP modes.

(5) Repeat paragraph 10 above.

12. Internal Pressure < 3000 PSI

a. Performance Check

(1) Set the TI power switch to ON. When the TI starts up it gives a Full Scale

pressure on the display. Record this number; it is the number to use for full-scale pressure.

(2) Start the Compass for Pressure program. Copy and modify the 610-700 mb

program to the pressure needed. For pressures greater than 55 PSI use pressure standard

no. 2.

(3) Allow the instrument's temperature to stabilize for a minimum of 1 hour.

(4) Connect the outlet port of the TI to Piston Gauge 2.

(5) Press the INPUT key and, using the up/down and left/ right arrows, select

PRESSURE INT then ENTER.

(6) With zero pressure applied, press the ZERO button and zero the pressure

reading.