TB 9-5210-219-40

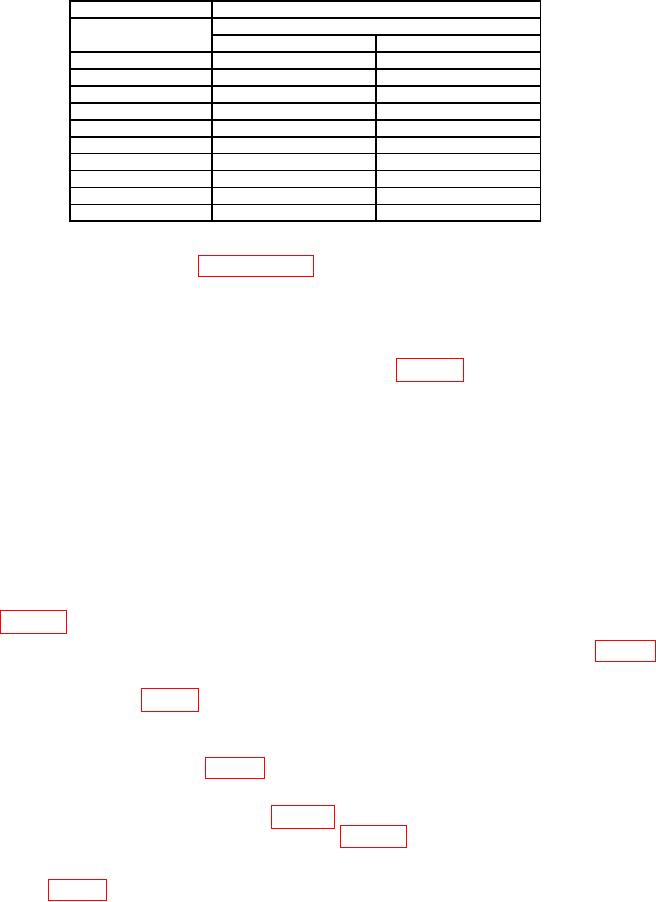

Table 3. Angle Indication

Test instrument1

Index table

Applied angle

Limits (degrees)

(degrees)

Min

Max

5

4.9 (4.9)

5.1 (5.1)

15

14.9 (14.7)

15.1 (15.3)

30

29.9 (29.5)

30.1 (30.5)

45

44.9 (44.3)

45.1 (45.7)

59

58.7 (N/A)

59.3 (N/A)

355

-5.1 (-5.1)

-4.9 (-4.9)

345

-15.1 (-15.3)

-14.9 (-14.7)

330

-30.1 (30.5)

-29.9 (-29.5)

315

-45.1 (-45.7)

-44.9 (44.3)

301

-59.3 (N/A)

-58.7 (N/A)

1 Indications in parenthesis are for models with 45 degree range.

b. Adjustments. Perform paragraph 15 below.

9. Angle Indication (Alternate Method)

a. Performance Check

(1) Setup equipment on surface plate as shown in figure 1 above.

(2) Use precision level to level sine plate length and width to within 10 arc-sec.

(3) Set TI to On and ensure display is set for degrees.

(4) TI will indicate between -0.1 degrees and 0.1 degrees. If TI indication is not

within limits perform b below.

(5) Rotate TI 180 degrees on sine plate to same location. TI will remain right side

up facing away from technician.

(6) TI will indicate between -0.1 degrees and 0.1 degrees. If TI indication is not

within limits perform b below.

(7) Rotate TI 180 degrees on sine plate to same location against sine plate side rails

as in figure 1.

(8) Wring together a gage block stack equal to corresponding value listed in table 4.

(9) Insert gage block stack into sine plate. If TI indication is not within limits

specified in first row of table 4, perform b below.

(10) Rotate TI 180 degrees on sine plate to same position against sine plate rails. TI

will remain right side up and face away from technician. If TI indication is not within

limits specified in second row of table 4, perform b below.

NOTE

Negative values listed in table 4 are a result of rotating TI

180 degrees from position shown in figure 1.

(11) Repeat technique of (7) through (10) above. If TI indication is not within limits

specified in table 4, perform b below.